Pulsed Laser Deposition Facility

The Pulsed Laser Deposition Facility (PLDF) is an interdisciplinary facility within the Superconductivity Research Group. It provides for the growth of thin films of oxide materials based primarily on High Temperature Superconductors.

Observing the plume of ablated material whilst depositing a film in the PLD facility.

Process

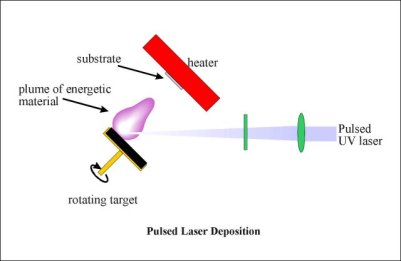

A target of the material to be deposited is irradiated by pulsed UV light in a low pressure of gas (usually oxygen). A process known as ablation then occurs and a plume of energetic particles are produced. This material is then deposited on a substrate which has been chosen for the best crystallographic, material and electrical properties. The primary parameters which govern film quality are:

A schematic diagram of the principle of operation of the laser ablation system

Facilities

The PLDF consists of a LambdaPhysik LPX200i Excimer laser running at 248 nm (KrF). The beam is then directed into any one of four chambers, these are dedicated to:

In addition to the deposition equipment the laboratory is equipped with a range of characterisation tools including AFM, STM, optical microscopes and critical current measuring apparatus. Access is also avalable to campus wide facilities such as VSM, SEM, TEM and XRD.

History

The facility was set up in 1992 and funded by the university. Since then we have been sucessful in obtaining grants for day to day running costs and expansion of facilities from SERC and EPSRC. In this period the facility has grown well in excess of 1000 films both for use within this university and at labs around the world.